HOME

HOME- Technology

- Development

Development

Research & Development

To produce high quality products that meets or exceeds customer’s needs, DaiHan Anchor Chain Mfg. Co., Ltd. invests & supports constantly in R & D. Continuous investment in R & D is the first step toward customer satisfaction.

Design development of

Offshore Mooring Chains

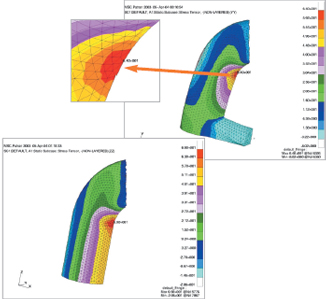

Finite Element Analysis

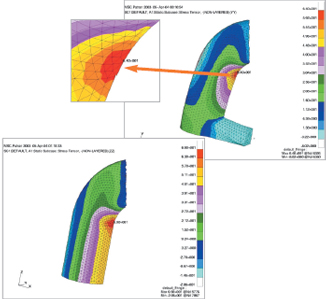

We satisfy customers’ needs by determining stress distribution that affects the link in the Mooring system through FEA(Finite Element Analysis) method when developing chain or changing design.

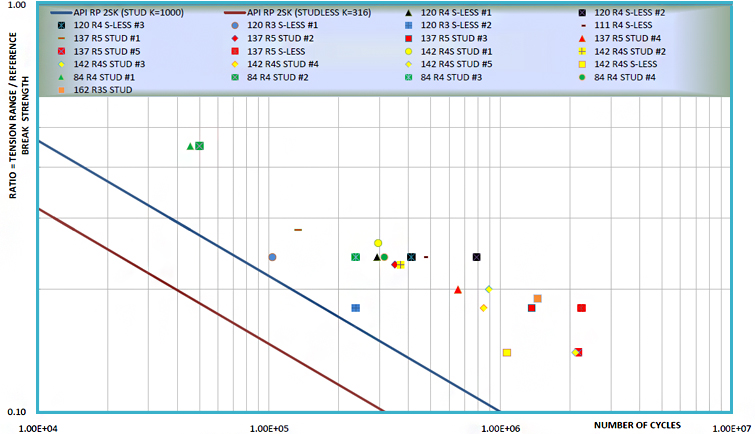

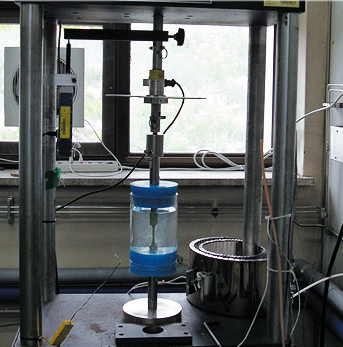

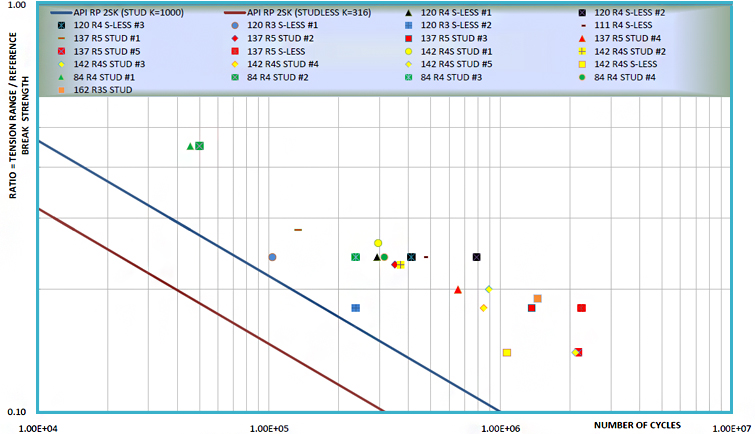

Fatigue Life Test

A Mooring Chain has to endure at least 25 years in tides,

winds and the corrosive & harsh offshore environment.

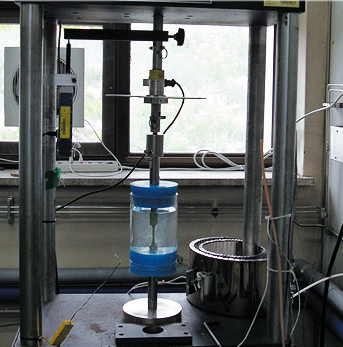

For this reason, the fatigue life of a chain is the utmost importance. We installed 6300kN Fatigue Tester to test fullscale

chain and accessories for each grade (R5, R4S, R4, R3S & R3) at air and salt water conditions, and also make efforts to develop long-term Fatigue Life Chain.

S-N Fatigue Curve

Stress Corrosion Crack

Mooring Chains used in a harsh offshore environment are vulnerable to fracture due to Stress Corrosion Crack undertensile stress and corrosion conditions. DaiHan Anchor Chain Mfg. Co., Ltd. carries out Stress Corrosion Cracking Test for Mooring Chain in collaboration with Korea Atomic Energy Research Institute under various conditions in order to manufacture and design the best quality chains to prevent early cracking.

Higher Strength Chain

We are developing extra high strength materials for Mooring Chains in collaboration with SeAH Besteel Corp., who is special steel manufacturer and will promote Grade R6 mater

ial development steadily as our joint research project.

Grade

Tensile Strength

Remarks

R4S

960 Mpa

Completed

R5

1000 Mpa

Completed

R6

1200 Mpa

On-going Project

Advantages of higher strength chain

• Reduce weight when installation of mooring chains

• Improve the mechanical properties of chain by Double

Heat Treatment(Double quenching & tempering)

• Increase fatigue life of chain

CTOD Test

(Crack Tip Opening Displacement Test)

Mooring Chain used for the safe installation of offshore structures require Mechanical Properties Test(Tensile Strength and Impact value) as well as CTOD Test for soundness evaluation for the chains. Team up with Doosan Heavy Industries & Construction, we carry out full scale CTOD tests for mooring chains of each grade and temperature with full scale specimen.

| Design development of Offshore Mooring Chains |

|---|

Finite Element AnalysisWe satisfy customers’ needs by determining stress distribution that affects the link in the Mooring system through FEA(Finite Element Analysis) method when developing chain or changing design. |

| Fatigue Life Test |

|---|

A Mooring Chain has to endure at least 25 years in tides,

winds and the corrosive & harsh offshore environment.

For this reason, the fatigue life of a chain is the utmost importance. We installed 6300kN Fatigue Tester to test fullscale

chain and accessories for each grade (R5, R4S, R4, R3S & R3) at air and salt water conditions, and also make efforts to develop long-term Fatigue Life Chain.

|

| Stress Corrosion Crack |

|---|

Mooring Chains used in a harsh offshore environment are vulnerable to fracture due to Stress Corrosion Crack undertensile stress and corrosion conditions. DaiHan Anchor Chain Mfg. Co., Ltd. carries out Stress Corrosion Cracking Test for Mooring Chain in collaboration with Korea Atomic Energy Research Institute under various conditions in order to manufacture and design the best quality chains to prevent early cracking.

|

| Higher Strength Chain | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

We are developing extra high strength materials for Mooring Chains in collaboration with SeAH Besteel Corp., who is special steel manufacturer and will promote Grade R6 mater

ial development steadily as our joint research project.

Advantages of higher strength chain• Reduce weight when installation of mooring chains• Improve the mechanical properties of chain by Double Heat Treatment(Double quenching & tempering) • Increase fatigue life of chain |

| CTOD Test (Crack Tip Opening Displacement Test) |

|---|

| Mooring Chain used for the safe installation of offshore structures require Mechanical Properties Test(Tensile Strength and Impact value) as well as CTOD Test for soundness evaluation for the chains. Team up with Doosan Heavy Industries & Construction, we carry out full scale CTOD tests for mooring chains of each grade and temperature with full scale specimen. |