HOME

HOME- Technology

- Technical Centrol

Technical Control

Technical Control

At DaiHan, each employee is dedicated to making the very best product possible through technological competitiveness and

strict quality management.

| Heat Treatment |

|---|

|

For higher strength quality chains (Grade R4S & R5),

we can reduce retained Austenite Structure in the chain through Double NDT system(Double quenching &

tempering) and can obtain Fine Grain size as well as securing the homogeneity of microstructure. In addition, we are trying to increase impact strength by improving the ductility of welding area of chain and endeavor to make longer Fatigue Life of the Chain.

|

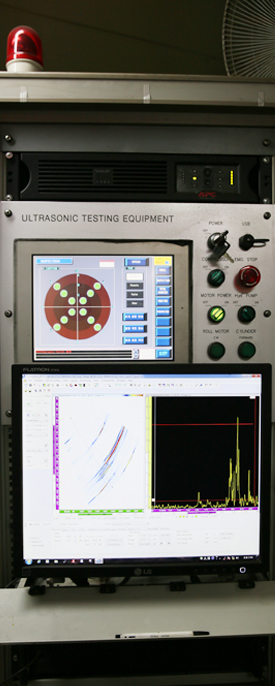

| NDT system |

|---|

To make up for the disadvantages of conventional UT(Ultrasonic Test) and to detect embeded defects stably & reliably, Phased Array type Automatic UT system with the vertical inspection lines has been introduced & installed for better inspection efficiency and accuracy.

Advantage

|

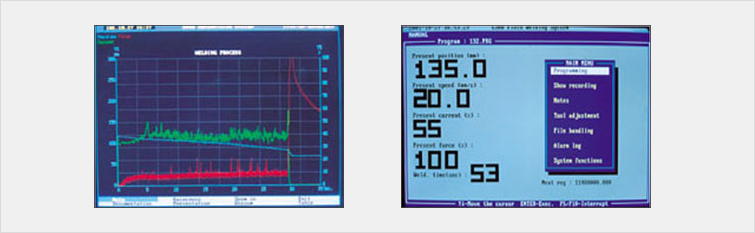

Flash butt welding

Regular calibration of high-quality welding machine(ESAB) and standardization of optimum welding conditions have contributed to quality enhancement on the welding line. The results of welding operations for chain cables are automatically recorded on the computer zip drive for perfect product traceability.